Polyaspartic and polycuramine are both durable coatings for concrete floors. Polyaspartic is known for its rapid curing time, while polycuramine boasts enhanced adhesion properties.

Exploring floor coatings for your garage or industrial space leads to a critical comparison between polyaspartic and polycuramine. Both offer robust protection against chemicals, abrasion, and UV radiation, making them popular choices. Polyaspartic coatings are often praised for their quick application process, allowing floors to be used within a day; this is highly beneficial where downtime is a concern.

Polycuramine, on the other hand, while it may take longer to cure, provides an exceptionally strong bond with concrete surfaces, ensuring long-lasting durability. Understanding these distinct qualities is vital for selecting the right coating that meets specific functional and operational needs.

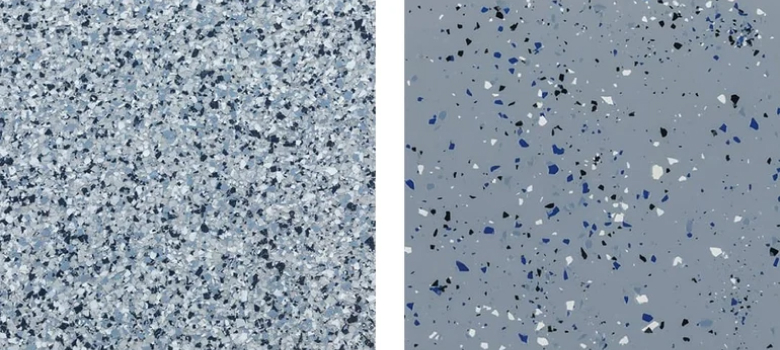

Credit: evolutionepoxy.com.au

Basics Of Floor Coatings

Choosing the right floor coating is crucial to protect and enhance your concrete floors. From garages to warehouses, safety and durability stand as priority. Today, we dive into the nitty-gritty of two popular choices: Polyaspartic and Polycuramine.

Durable Solutions For Concrete

Both Polyaspartic and Polycuramine coatings offer incredible protection. They withstand heavy traffic, resist stains, and repel chemicals without fading or peeling. Here’s a quick comparison:

- Polyaspartic – Fast curing, UV stable, and extends floor life.

- Polycuramine – Extreme durability, excellent adhesion, and a high-gloss finish.

Chemical Makeup Of Floor Coatings

Understanding the chemical base of any floor coating is vital. It affects the application process, curing time, and final look. Polyaspartic and Polycuramine have unique compositions:

| Coating Type | Base Compound | Characteristics |

|---|---|---|

| Polyaspartic | Aliphatic polyurea | Long-lasting, UV resistance, quick cure rates |

| Polycuramine | Modified polyurea | Bonds strongly, resists abrasions, and endures extreme temperatures |

Credit: allgaragefloors.com

Polyaspartic Coatings

Amidst the array of floor coatings, Polyaspartic coatings stand out for their resilience and versatility. Originally designed for industrial applications, they’ve found favor in residential and commercial spaces. Polyaspartic coatings offer exceptional durability and rapid installation, making them a top choice for busy environments.

Rapid Cure Times

Polyaspartic coatings radically reduce waiting times. Their fast curing process allows for a return to service often within a day. This quick turnaround is ideal for spaces that cannot afford long downtimes.

- Touch-dry in 1-2 hours

- Full cure in 24 hours

- Potential for same day application and use

Uv Resistance And Color Retention

The fight against fading is won with Polyaspartic coatings. They boast excellent UV resistance, ensuring colors remain vibrant longer. Outdoor spaces benefit greatly from this resistance, negating the typical yellowing seen with many other coatings.

| Feature | Benefit |

|---|---|

| UV Resistant | Prevents yellowing and fading |

| Color Retention | Maintains aesthetic appeal over time |

Application Conditions And Limitations

Environmental conditions impact the application of Polyaspartic coatings. Optimal results require specific temperatures and humidity levels. Limits exist:

- Temperature: Apply between 0°C and 35°C

- Humidity: Below 85% for best results

- Clean Surface: Free from oil, dirt, and debris

Strict adherence to these conditions ensures a smooth, flawless finish. Yet, Polyaspartic coatings stand forgiving to slight deviations, remaining workable in sub-optimal circumstances.

Polycuramine Coatings

Exploring the world of garage floor coatings leads us to the powerful and engaging Polycuramine Coatings. Known for their durability and aesthetic appeal, these coatings are becoming a go-to choice for many. Let’s dive into what makes Polycuramine stand out.

Strength And Flexibility

Polycuramine coatings boast unmatched strength and flexibility. Their robust nature ensures floors resist chemicals, stains, and impacts. The flexibility of Polycuramine allows it to absorb impacts without cracking, a critical feature for high-traffic areas. This combination makes it a superhero in the realm of floor coatings.

Best Scenarios For Polycuramine Use

- Garages: Vehicle traffic demands enduring surfaces.

- Workshops: Equipment and heavy items require tough floors.

- Commercial Spaces: High foot traffic needs lasting endurance.

- Showrooms: Beauty and durability create appealing displays.

Ease Of Application And User Friendliness

Polycuramine is user-friendly. Its low odor and quick curing time mean you can apply it with ease and get back to using your space quicker than traditional epoxy coatings. DIY enthusiasts and professionals alike appreciate the straightforward application process, which includes a simple roll-on procedure.

| Feature | Benefit |

|---|---|

| Low Odor | Comfortable to use indoors |

| Quick Curing | Space is usable sooner |

| Easy Application | No special tools required |

Comparing Performance Factors

When deciding on the best floor coating, performance is key. Polyaspartic and polycuramine are top contenders. Both offer unique benefits. Let’s dive into their performance factors.

Weather And Chemical Resistance

Polyaspartic coatings excel in weather resistance. They withstand extreme temperatures. UV stability is a key feature. These coatings resist fading and yellowing. They also handle chemical spills well.

Polycuramine, although durable, might be less UV resistant. Its chemical resistance is top-notch. It can encounter common garage chemicals without damage.

Adhesion And Abrasion Ratings

Both coatings adhere strongly to concrete surfaces. Polyaspartic has a swift bonding time. Floors are ready to use in a day. Abrasion ratings for polyaspartic are high.

Polycuramine also has reliable adhesion. But, it may need more time to set. Its abrasion ratings are good. It offers a thick finish that protects from wear and tear.

Maintenance And Longevity

Maintenance for polyaspartic floors is minimal. Clean them with a simple mop or sweep. These floors last long. Expect them to look new for many years.

Polycuramine floors are also low-maintenance. They resist stains with ease. Longevity is similar to polyaspartic, ensuring a lasting finish.

Economic Considerations

When choosing between Polyaspartic and Polycuramine coatings, it’s vital to understand their economic impact. In this section, we compare the costs, analyze the life cycle, and examine warranty options to make an informed decision.

Cost Comparison

The initial price tag of any floor coating is a crucial factor. Polyaspartic coatings tend to be more expensive upfront when compared to Polycuramine. This difference results from the materials used and the application process, which often requires professional installation. Prices can vary widely depending on the size of the area to be covered and the complexity of the job.

Life Cycle Analysis

Considering the longevity of a floor coating can lead to cost savings over time. Polyaspartic coatings are known for their durability and resistance to UV light, chemicals, and abrasion. They tend to last longer, meaning fewer applications over the years. Polycuramine, while also durable, may not fare as well in high-traffic areas or under intense exposure, potentially leading to more frequent reapplications.

Longevity Factors:

- Polyaspartic: typically 20+ years

- Polycuramine: typically 10-15 years

Warranty And Guarantee Offerings

Warranties can mitigate financial risks. Most Polyaspartic coatings come with extensive warranties, some offering coverage for up to 15 years. These warranties protect against defects and premature wear. In contrast, Polycuramine coatings often have shorter warranty periods, reflecting their expected usable life. Always read the fine print to understand what is covered.

Typical Warranty Lengths:

| Type of Coating | Warranty Length |

|---|---|

| Polyaspartic | Up to 15 years |

| Polycuramine | Up to 5 years |

Real-world Applications

Welcome to the practical world of durable floor solutions where Polyaspartic and Polycuramine coatings shine. This section dives into real-life uses. These high-performance coatings protect and beautify floors across various sectors.

Case Studies: Polyaspartic Floors

Polyaspartic floors offer remarkable benefits:

- Fast curing time makes them ideal for busy commercial environments.

- Resistance to UV light ensures colors remain vibrant over time.

- High durability suits high-traffic areas like airports and hospitals.

Real-world examples include:

- A retail store in New York chose Polyaspartic coating to keep floors glossy despite heavy foot traffic.

- An auto dealership applied it for its quick turnaround and resistance to oil stains.

Case Studies: Polycuramine Floors

Polycuramine excels in flexibility and strength:

- Withstands extreme temperatures, suitable for workshops and garages.

- Resists chemicals and abrasions, ideal for industrial facilities.

Case studies highlight its effectiveness:

- A homeowner in Minneapolis used Polycuramine for a garage floor that endures long winters and road salt.

- A manufacturing plant reported no wear after years of heavy machinery traffic.

Expert Opinions And Recommendations

Flooring experts often recommend:

- Polyaspartic for commercial spaces needing quick return to service.

- Polycuramine for basements and garages due to its moisture resistance.

Experts also suggest considering the specific needs of the area before choosing:

| Aspect | Polyaspartic | Polycuramine |

|---|---|---|

| Temperature | Less sensitive | Highly flexible |

| UV Stability | Does not yellow | Can discolor over time |

| Application Window | Narrow | Wide |

| Cure Rate | Fast | Medium |

Take into account foot traffic, exposure to elements, and downtime for application. Both coatings offer robust protection - the final choice hinges on specific project needs.

Credit: www.homedepot.com

Conclusion

Choosing between polyaspartic and polycuramine coatings depends on your specific needs. Consider factors like project timeline, budget, durability requirements, and aesthetic preferences. Both options offer robust solutions, yet each has its distinct advantages. For a swift, resilient surface, polyaspartic stands out.

If time allows for a meticulous application and you desire enhanced visual effects, polycuramine might be your go-to. Careful selection ensures a lasting, high-quality finish for your floors.

I’m Robert M. Payne, a passionate enthusiast for turning houses into dream homes. With a knack for DIY projects and a keen eye for design, I’ve dedicated myself to sharing my knowledge and experiences in the realm of home improvement.

As a seasoned homeowner and avid DIYer, I understand the challenges and joys that come with transforming living spaces. Through Myhomemyworld, I aim to inspire and guide fellow homeowners on their journey to creating spaces that reflect both functionality and style.

Cheers to creating spaces that truly feel like home.

Connect with me in facebook